They are specifically built to answer potato processors requirements with:

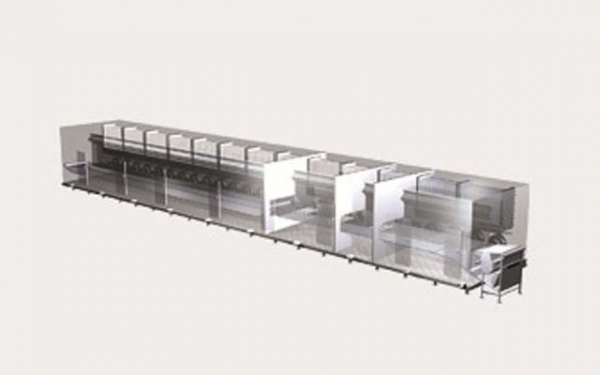

The new AY-series IQF tunnels integration of this technology exceeds food processors’ expectations in product quality, low product dehydration and low product clumping.

The GEA AY-series even eliminates the need for liquid nitrogen pre-crusting before freezing for highly sensitive products such as raspberries. By combining even air distribution, high air pressure and gentle mechanical product agitation, not belt shaking, the GEA AY-series ensures true fluidization.

Capable of processing 1.5 to 15+ tons per hour (based on green peas), our AY-series IQF tunnel freezers are specifically built for:

Higher Yield

Large capacities

- Up to 25 tons per hour freezing capacity

Higher Yield

Cost effective IQF treatment

Multiple temperature zones

- Precooling

- Refrigerating

- Freezing

Hygienically engineered design

- Fully welded stainless steel floor, enclosure and structure

- Ample access to all components

Energy saving solutions

- Precool section using thermosyphon ammonia. No refrigerating compressors required.

- Precool section using plant water heated from +15°C to +22°C. Energy saving in the factory hot water system.

- Freezing section using ammonia at -32°c. More than 20% energy saving in comparison with -40°C evaporating temperature.