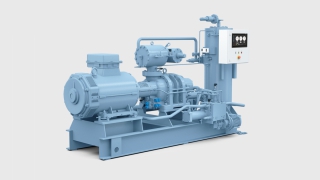

The world-class quality of our screw packages is the product of years of experience in compressor technology. Everything is focused on value and functionality from development in our research labs to the production processes and quality assurance. The high reliability and long life of our GEA screw compressor packages is the result of fifty years of experience in compressor technology.

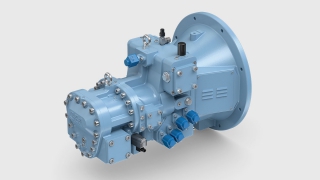

Everything began with a series of single-stage packages. Today we produce various models with more than 50 different package sizes. They are suitable for the operation with natural and all other common refrigerants. Next to our standard models we also produce tailor-made solutions for customer-specific needs.