Welcome to GRADE Refrigeration LLC SP

GRADE is the successful formula of combining local engineering, service, manufacturing and execution capacity.

Keeping it cool with GRADE

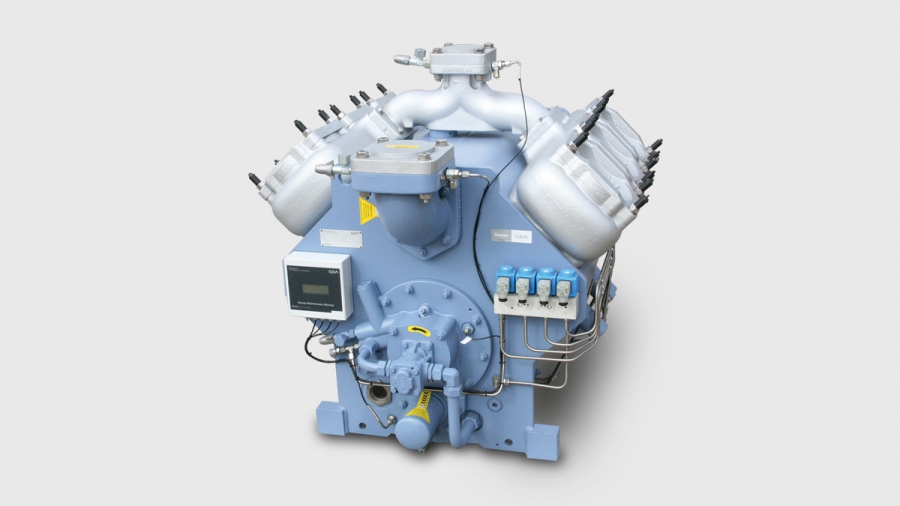

GRADE is active in contracting and equipment supply for industrial refrigeration and provides genuine solutions for any refrigeration application