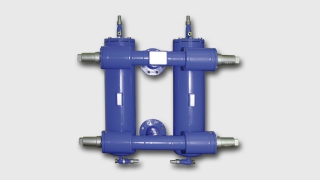

Suitable for use with natural refrigerants, non-corrosive gases and liquids, and cooling brine. These valves and components are perfectly designed, developed, and manufactured in accordance with your specifications.

Certified by the following internationally recognized classification authorities:

- German Technical Inspection Agencies (TÜV)

- Lloyd’s Register of Shipping (LRS)

- Bureau Veritas Certification (BV)

- Russian Maritime Register of Shipping (RS)

- Urzad Dozoru Technicznego (UDT)

- NIPPON KAIJI KYOKAI (ClassNK)

- Rostechnadsor (RTN)

- Gossudarstwenny Standart (GOST)

- Germanischer Lloyd (GL)

- Det Norske Veritas (DNV)